Can UV Lasers Engrave Inside Glass? What Buyers Need to Know

GK

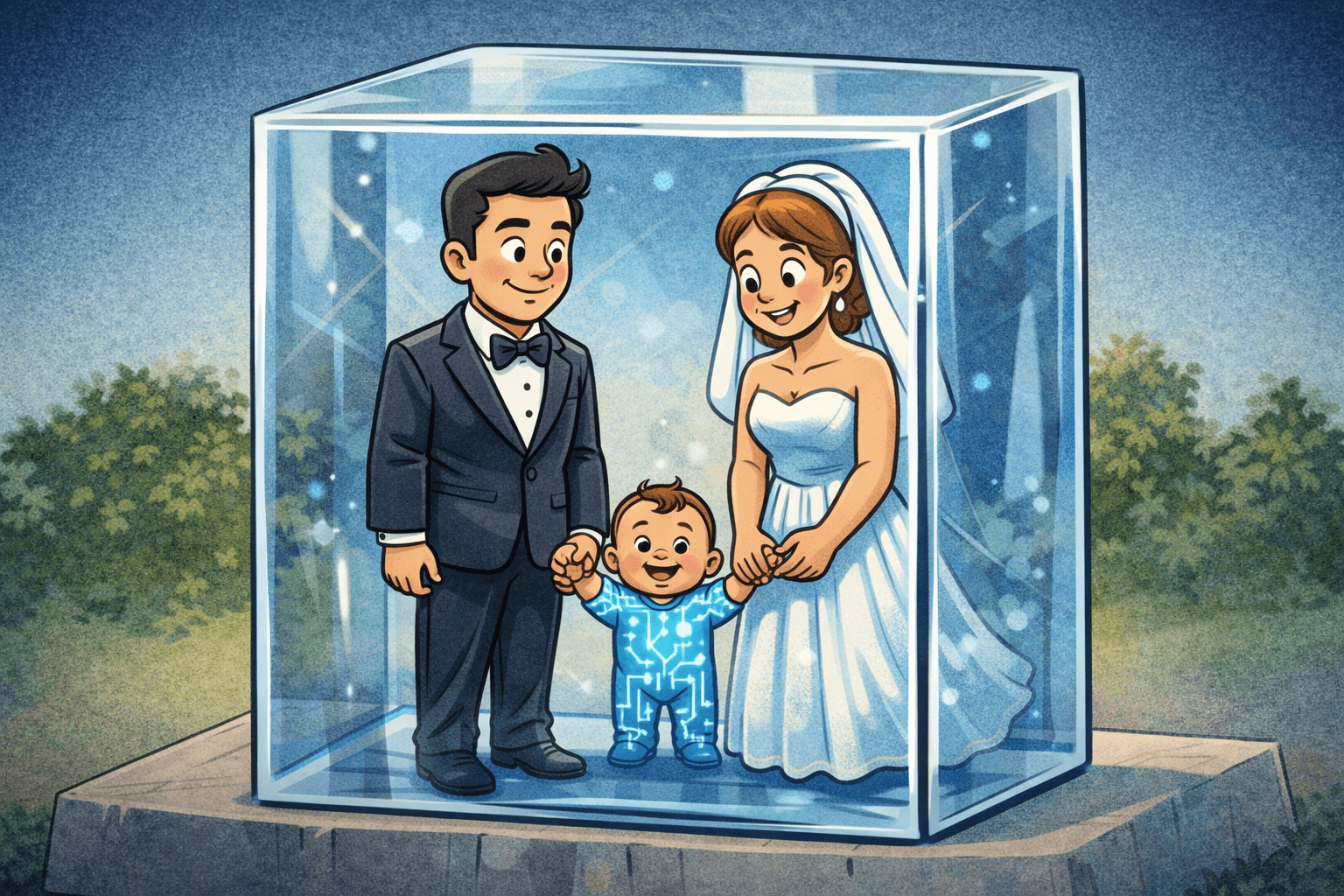

Every once in a while, something changes in the laser industry and everyone involved suddenly agrees not to talk about it honestly. Manufacturers smile, spec sheets get longer, and YouTube influencers line up like nervous fathers at a shotgun wedding — smiling for the camera, saying all the right things, and hoping no one asks how this union actually came together. Meanwhile, buyers are left staring at machines that absolutely could not do something a year ago, now doing it effortlessly, with no real explanation. That’s exactly where we are today with UV lasers and interior glass engraving. A marriage just happened — and no one saw the engagement.

So the only reasonable question is: where did that baby come from?

What I’m about to share is simply my due diligence at this point in time. While some people consider me a laser expert, I don’t see myself that way at all. I’m a trust but verify type of person. Things move incredibly fast in the laser world, and what I write today could very well be outdated next week. That’s not a weakness — it’s just the reality of this industry.

Until very recently, UV lasers lived in a fairly well-defined lane. They were excellent at surface engraving — glass, plastics, coated metals, ceramics, and all the other materials UV excels at. What they did not do, at least not at an approachable price point, was interior glass engraving. That capability belonged to a different class of machine entirely. If you wanted to engrave inside glass cubes, you paid real money for it, because those systems relied on extremely fine dot control, precise pulse timing, and controllers purpose-built for point-cloud work inside transparent materials. There wasn’t much debate about it. That was simply how the technology worked.

For years, companies like STYLECNC built their reputation on exactly that traditional model. Purpose-built interior engraving systems, extremely fine dot sizes, and machines designed to do one job exceptionally well. Those machines still matter. In fact, they still win outright when absolute detail is the priority. Their dot size is orders of magnitude smaller than what these new hybrid UV machines can currently produce, and when you’re chasing the finest possible interior detail, that advantage hasn’t disappeared.

What changed isn’t that those machines suddenly became obsolete. What changed is that interior engraving is no longer exclusive to them, and prices have fallen to a point where the machines are in reach of more people.

Almost quietly, two companies stepped out of line. XLaser Labs with the E3, and xTool with the F2 UV, both entered the conversation claiming something that, not long ago, would have raised more than a few eyebrows. These machines are being positioned as UV systems capable of engraving inside glass cubes while also engraving the exterior of glass and handling the full range of normal UV surface materials. That combination matters. Interior engraving itself isn’t new — what’s new is that it’s suddenly appearing in machines that are not dedicated, single-purpose crystal engravers.

Historically, that crossover simply didn’t exist at this price and size class, largely because the controller requirements were different. Interior engraving depended on controllers capable of producing extremely fine, tightly controlled dots, while surface UV engraving prioritized versatility and speed. Those two worlds rarely overlapped. So when machines like the E3 and F2 UV show up claiming to do both, the real question isn’t whether they function — it’s how they’re being made to do it.

So how did this marriage between interior glass engraving and surface engraving begin? Was it accomplished through a new controller design, through software, or through some combination of the two? Right now, it feels like a few companies simply eloped, and the rest of the industry hasn’t quite caught up to what just happened.

What we do know is that laser machines, much like computers, are assembled systems. Controllers, laser sources, optics, firmware, and software are combined into a final product. When new capabilities appear this quickly across multiple brands, it almost always means something changed at the controller or software level rather than the laser source alone. Whether that change is a new controller architecture, a software-driven solution, or a hybrid approach is still unclear — but the shift itself is unmistakable.

And as sure as the sun comes up tomorrow, this won’t remain isolated. Whatever enabled this crossover capability will be copied, refined, and redistributed. In fact, even during the research for this article, another company entered the discussion with a hybrid-style machine, reinforcing the idea that interior glass engraving is no longer locked behind premium-only systems. Once that door opens, it doesn’t close again. There is also a rumor circulating that FEELTEK may be the brains behind this shift — if the breakthrough is truly controller-driven — but at this point, that remains unconfirmed.

For now, the market sits in an interesting transition. Traditional exterior engraving systems like those from Gweike still dominate and represent a strong, proven approach as they push further into the American market. The new hybrid UV machines trade some of that extreme precision for versatility — and for many users, that tradeoff will make sense. As more machines ship and more real-world data becomes available, the strengths and limitations of each approach will become much clearer.

At this point in time, if I were personally forced to make a purchasing decision, my preference would lean toward the XLaser Labs E3. Not because it claims to be the most powerful or the most precise, but because it is a fully enclosed 10-watt UV system and, so far, it is the machine releasing the most complete and transparent specifications into the marketplace. The xTool F2 UV is a 5-watt machine, and logically it will not be as fast. Equally important, XLaser Labs is a manufacturer, not just a company assembling off-the-shelf components. They design and build the machines themselves, and that matters when evaluating long-term support, consistency, and engineering intent.

I also can’t move on without addressing the traditional tower-style UV laser. The open format does have advantages, particularly when working with larger or irregularly sized objects. Gweike is entering this market very aggressively, (under their own name) and at the time of writing they are clearly stating that their UV source is a JPT, which is a well-regarded manufacturer of laser sources. As time passes, it’s reasonable to ask whether a future software or controller evolution could allow machines like this to perform interior engraving as well. Today, that remains an open question — but it’s no longer an unreasonable one.

That preference may change as more information becomes available, more units reach customers, and more real-world testing is done. That’s the responsible position to take. Interior glass engraving didn’t suddenly become easy, and it didn’t suddenly become equal across all machines. What changed is accessibility. Interior engraving has been repackaged, integrated differently, and made visible to a much broader audience — and that shift is going to matter a lot more next year than it does today.